Apparel businesses are pressured to overcome the increasing labor costs across China and ASEAN countries and the impact brought by the COVID-19 pandemic to this industry. Developed alongside Brother Machinery (Asia) Limited, our latest white paper “Digital Transformation in the Apparel Industry: How to Improve Efficiency in Apparel Factory Supply Chain” suggests that digitalization is vital to address the current challenges in the apparel industry.

The strict pandemic lockdown has resulted in the apparel industry to lose over 70% of functions and has decreased the total sewing machine operating hours in India, Bangladesh, Vietnam, and Indonesia to 27%. Consequently, this brings new opportunities for apparel brands to look at digital options for their business. The COVID-19 pandemic has accelerated the push for digital transformation, with global spending on digital transformation technologies and services expected to increase to USD 1.3 trillion by the end of 2020.

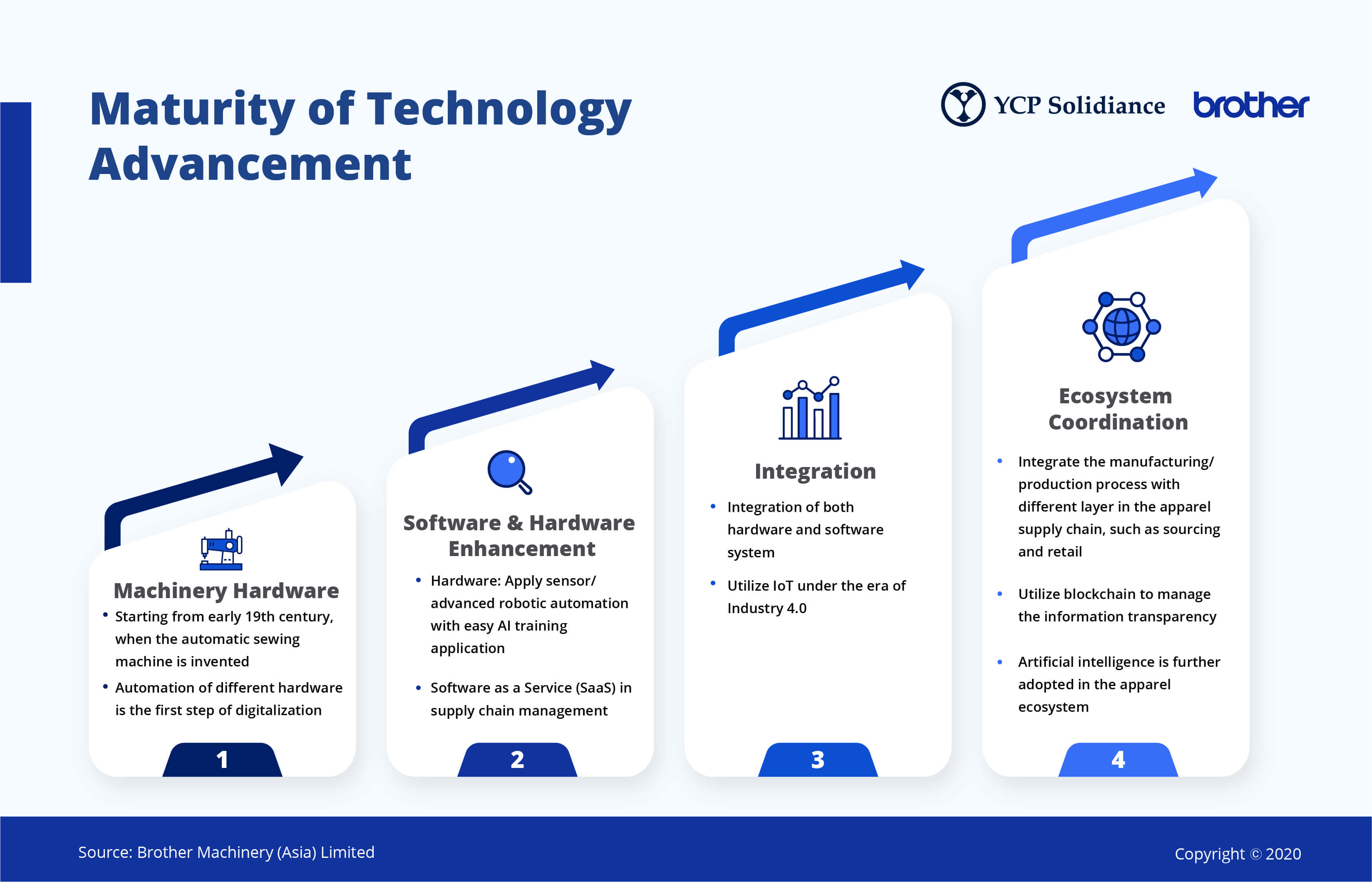

Bringing the Apparel Industry Forward through Digitalization

Integrating digital technology, such as IoT systems and automated machinery, is proven effective to boost apparel production by 5% and reduce 88% overall time and costs. About 75% of apparel manufacturers are also planning to adopt AI technologies to improve their supply chain’s flexibility. To effectively adopt digital transformation, our research suggests some critical considerations for apparel brands:

- Understand the Needs

Identifying current problems and possible digital-related actions to solve problems. - Make Initiative Prioritization

Conducting assessments towards the urgency of prioritized problems and practical solutions. - IoT and Visualized Data Implementation

Integrating IoT systems enable the data for each line and process to be correctly analyzed. - Data Analysis and Action

Providing analysis of the improvement point for the manufacturers’ side.

Apparel manufacturing players should start investing digital technology in their activities as more technologies will enhance the apparel industry. Download our report to find out more about digital opportunities in the apparel industry.